Category

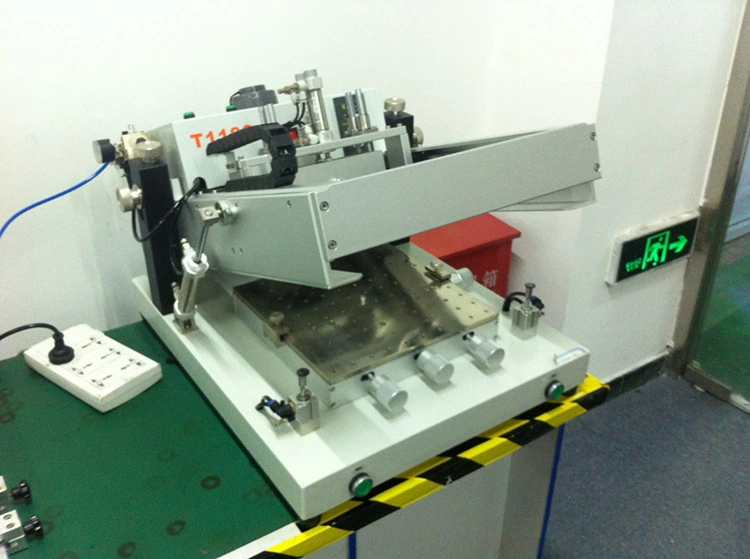

Torch T1100 Semi Automatic High Precision Solder Paste PCB SMT Stencil Printer

TORCH T1100 Semi automatic high precision Solder Paste PCB SMT Stencil Printer It is semiautomatic screen printer which

Basic Info.

| Model NO. | T1100 |

| System Supported | Windowsxp64 |

| Max Power | 50W |

| PCB Size | 220 * 180mm; 220*240mm |

| Input Voltage | AC220V |

| Template | Lift Automatcally |

| Dimension | 740*554*400mm |

| Squeegee | Dual Drive by Motor |

| Transport Package | Plywood |

| Specification | CE ISO SGS |

| Trademark | TORCH |

| Origin | Beijing |

| HS Code | 8443192290 |

| Production Capacity | 30 Month |

Product Description

TORCH T1100 Semi automatic high precision Solder Paste PCB SMT Stencil Printer

It is semiautomatic screen printer which has PLC program controlling, high accuracy, low

Malfunction; The lift of support shelf and scraper is driven by air, there are speed valve in exit

And entrance which can adjust speed; The speed of scraper is controlled by motor, speed timing

Of motor can control motor speed; Scraper is made of steel stainless

Main technology parameters

Max PCB 230× 180mm (Standard), 220*240( optional)

Working table area 300× 300 mm

Template size 300× 400 mm

Air pressure 0.4-0.7Mpa

Input voltage AC220V

Max power 50W

Dimension 740× 554× 400mm

T1100 is a high accuracy semiautomatic printing machine. The operator only needs to press the

Double switch button at one time. Then the printing machine will automatically finish the single

Pass of the printing process. After the printing is done, take out the PCB plate and put it into the

Turnover box or directly into the mount machine. In the end put another PCB in the printing

Machine to go on with the next printing cycle.

Features for this model: Simple operation, high accuracy, easy to be adjusted, widely used and

So on.

1. PLC control system.

2. Panasonic gear motor.

3. The imported linear guide track keeps smooth and exact printing

Lift air cylinder of back scraper

Lift air cylinder of front

Scraper

X axes

Adjust height of

Template

Height fixed handle

Configuration

1. Bench top semiautomatic screen printer T1100 1 set

2. Accessory

A. Position thimble 6

B. Support thimble 8

3. Accessory:

A. Testing report 1

B. Using manual

Adjust angle

Speed timing of motor

| Max print area | 220 × 180mm; 220× 240mm (optional) |

| Max steel seat size | 350x400mm |

| Frames size: | (400*350m) |

| Adjustable dual squeegee pressure/speed | Control by valve of cylinder |

| Adjusting stencil size/thickness | 350× 400mm/ 20mm |

| Squeegee | Drive by micro motor |

| Squeegee material | stainless steel |

| Adjustable motor-drive squeegee for single or dual passes | yes |

| Linear squeegee guide | Yes |

| Automatic power frame lift | yes |

| Magnetism thimble for double-sized PCBs | yes |

| Dual squeegee Adjustable angle of attack | Yes Yes |

| X & Y adjustment | +/-10mm |

| Z axis adjustment | 15mm |

| Θ adjustment | Counter rotating dual knobs +/-5 º C |

| Repeat accuracy | < 0.03mm |

| Adjustable accuracy | < 0.01mm |

| Ideal Max print accuracy | 0.4mm IC, BGA with ball diameter> 0.3mm |

| Power supply | AC220V, 50Hz |

| Max power | 60W |

| Air pressure | 0.4-0.7 Mpa |

| Dimension | 740× 554× 400mm |

| Accessories: | Thimbles 8 Support shelves 6 Inner hexangular spanners 1 Nuts and bolts 6 2 metersof air pipe. 1 |