Category

Robot Develop Autonomous Route Planning 5000kg Payload Robot Platform Smart Mobile Chassis Robot Automated Guided Vehicle Agv

Overview Package Size 200.00cm * 60.00cm * 200.00cm Package Gross Weight 500.000kg Product Description Automated Guided

Overview

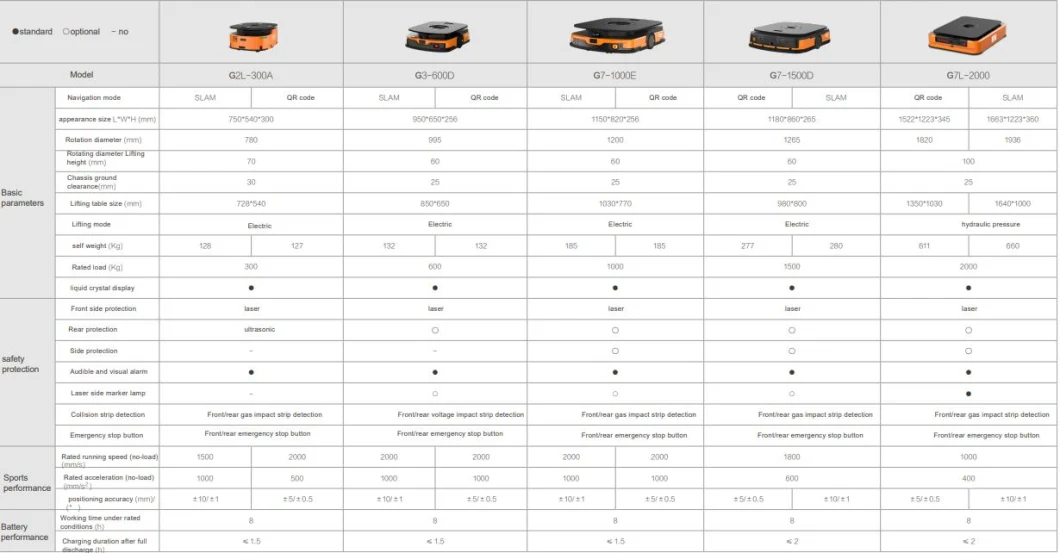

Product Parameters

FAQ

Basic Info.

| Model NO. | AGV |

| Drive Mode | Electric |

| Application | Welding, Loading, Forging |

| Condition | New |

| Certification | ISO, CE |

| Security System | Lidar Sensor; Bumper Sensor |

| Charging Method | Manual Charging/Auto Charging |

| Vehicle Weight | Less Than 250kg |

| Moving Speed | Max 0.6m/S |

| Walking Direction | Forward,Steer,Back |

| Battery | Lithium Battery |

| Load Capacity | 100-6000 Kgs |

| Transport Package | Wooden Box |

| Specification | L1100*W900*H380 Support customization |

| Trademark | JiaGong |

| Origin | Hebei China |

| HS Code | 8428904000 |

| Production Capacity | 2000piece/Month |

Packaging & Delivery

Package Size 200.00cm * 60.00cm * 200.00cm Package Gross Weight 500.000kgProduct Description

Product Description

Automated Guided Vehicle

AGV logistics trolley, also known as AGV logistics handling robot, can achieve straight line walking, left and right turn, in situ rotation (turn around), there are a wide range of applications in industry, such as: machinery processing plants, textile factories, food factories, warehouse transfer, etc.

At present, our company can standardize the mass production of AGV logistics trolleys with a bearing capacity of 1 ton,3 tons and 30 tons, and we can also customize AGV logistics trolleys according to specific needs.

| Agv Vehicle --- 3 Navigation Modes | |

| 1.Laser navigation | Laser navigation, used in the factory environment is not much change occasions, if the factory environment changes too much, AGV will not be able to identify the road conditions, thus reducing the utilization rate of AGV trolley. |

| 2.Magnetic stripe navigation | Magnetic strip navigation, for the ground in the factory laid magnetic strip, AGV through its own magnetic sensors andwireless.network control for movement, less affected by the outside world, widely used; |

| 3.Two-dimensional code navigation | Two-dimensional code navigation, the use of its own recognition of two-dimensional code function and factory Wireless network control, movement, less affected by the outside world, widely used. |

| Scheduling System Advantages |

| • Self-developed heavy-duty AGV controland magnetic navigation system areseamlessly linked to realize real-timescheduling and AGV operation data(normal operation status, fault information, parking status, chargingstatus, landmark information, etc.)collection, upload and display. |

| • Heavy-duty AGVs in JiaGong 'sdispatch system enable autonomous path planningas well as automated handling tasks. |

| • Realize manual editing ofroute maps and automaticimport by software. |

| • Realization of multi-berth basedloading and unloading tasks AGV automatic dispatching. |

| • Status updates for key locationsin each AGV path are displayedin the user interface, and landmark location informationfrom the magnetic navigationsystem is used as a referencemarker. |

| • Realize traffic control of multipleAGVs in the map pat. |

| Considerations for Purchasing Agv Logistics Trolley | |

| 1. | The purchaser must specify the weight (with or without pallets) and size of the products to be transferred. |

| 2. | The purchaser shall provide a road map of the operation of the AGV (with examples of the road map below), with video or photos of the AGV operation road (the supplier relies on the photos or videos to determine whether there is a risk of off-loading in the middle of the operation); if there are special sections, such as slopes, the length and slope of the slope and photos shall be provided (the supplier relies on the data and photos to determine whether there is a risk of the AGV chassis being scratched).(risk). The operation path must be clear, from the pickup place to the destination, how many times a day it needs to turn around, and how much the distance is, these three issues determine the area covered by the LAN and the time beat operation. |

| 3. | It is recommended that the purchaser purchase two charging piles (determined by the purchaser) to prevent running out of power midway and making charging difficult (AGVs have no power and are difficult to push and need to be charged with forklifts and other consignments). |

| 4. | Whether the pallet of AGV is provided by the buyer or the supplier must be clear. |

Q1: Are you manufacture or trading company?

Since 2003, we have started to provide overall warehouse solutions. We have two factories located in Tianjin and Nanning, China. Welcome to visit anytime.Q2:What information is required for stereo library quotation request?First of all, we need to know the number of your storage space, the maximum number of goods in and out per hour, and the size of the warehouse. This is a complex system, and we need to fully communicate.Q3:Could you produce according to customers' design?Of course, we have rich experience in the overall warehouse solution, and we need to build hundreds of projects every year.Q4:What's your trading terms?Deposit 40% upon signing the contract,the balance will be cleared by T/T before delivery.Q5:What is your delivery time?25-35 working days after received deposit,according to the order quantity and drawing size.Q6:How could I install the racks?We provide detailed instal instruction for every type of shelf. If needed,we can also ask engineers to teach you for free.Q7:What is the manner of packing?Generaly,shelves are flat packed by air bubble film in standard export cartons .Other packing likewooden box are available to clients' requirement.